登入

橡膠輸送帶

耐熱和耐火。

層間與覆蓋橡膠之間的良好附著力。

不變形。

優秀的可塑性。

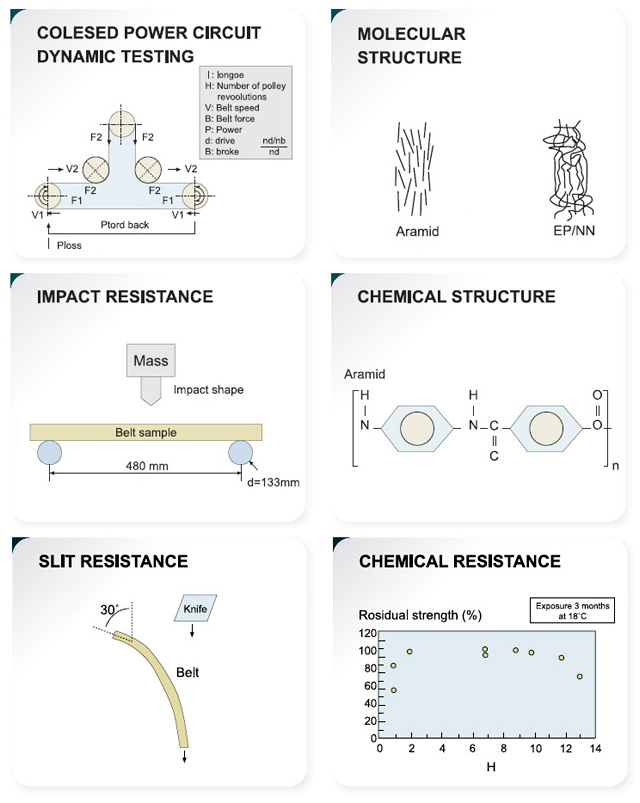

衝擊,穿透和抗切割性。

防止易燃材料滲透。

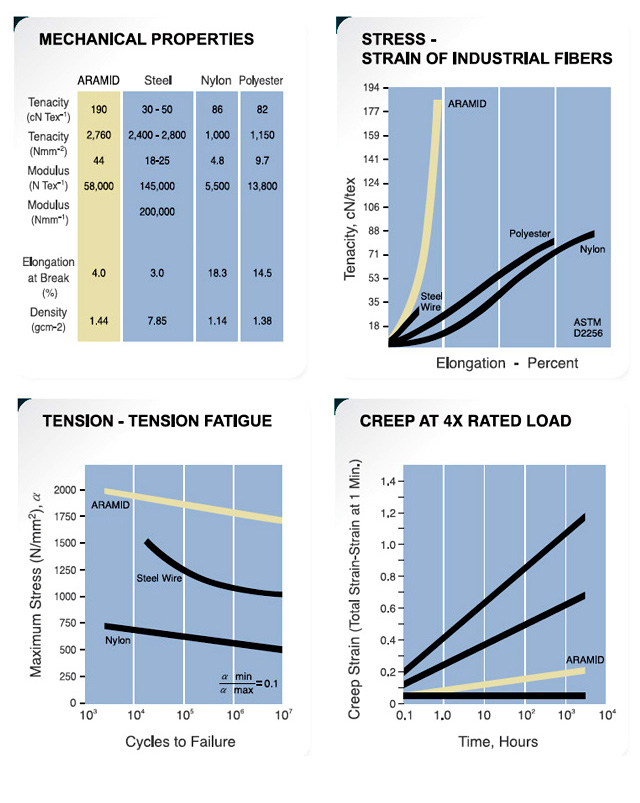

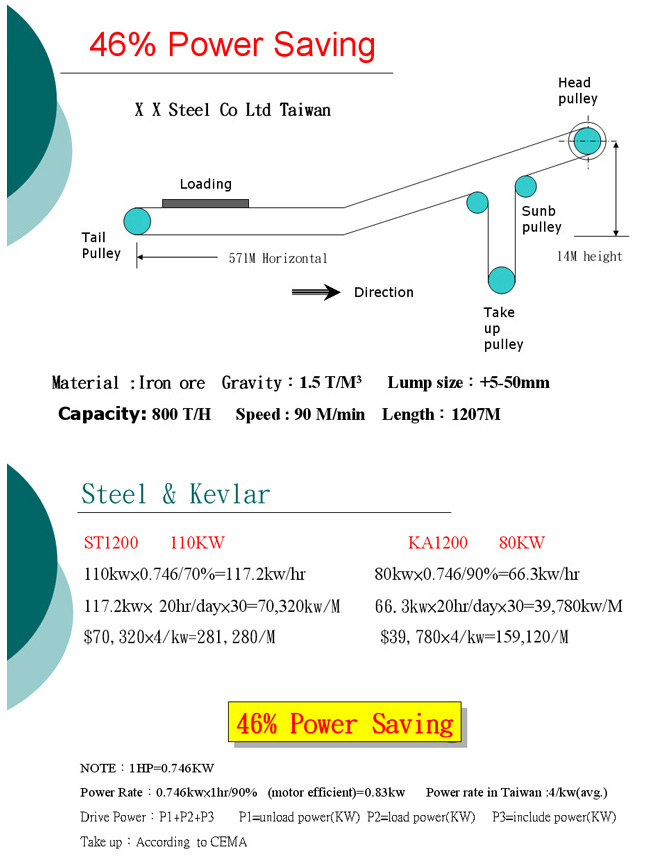

伸長率低。

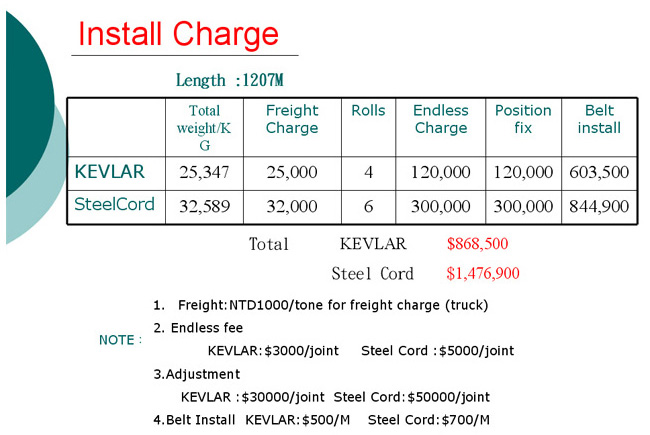

重量輕。

抗疲勞。

防腐蝕。

非導通。

彈性極大。

| Kevlar (R) | Steel | NN/EP | |

|---|---|---|---|

| Impact Resistance | ◎ | △ | ○ |

| Adhesion | ◎ | △ | ○ |

| Toughness | ◎ | △ | ○ |

| Slit Resistance | ◎ | △ | ○ |

| Elongation | ○ | ◎ | △ |

| Flamme Resistance | ○ | ◎ | △ |

| Static Electricity Proof | ◎ | △ | ○ |

| Corrosion Resistance | ◎ | △ | ○ |

| No Warp Cord Pop-out | ◎ | △ | ○ |

| Flexibility | ◎ | △ | ○ |

| Light Weight | ◎ | △ | ○ |

| Fatigue Resistance | ◎ | ○ | △ |

| Splicing Time | ○ | △ | ◎ |

| Belt Life | ◎ | ○ | △ |

| Flexibility When Overload | ◎ | △ | ○ |

| Min. Power | ◎ | △ | ○ |

| Smaller Dia Pully | ◎ | △ | ○ |

| Splicing Life | ◎ | ○ | △ |

| Min. Facility Cost | ◎ | △ | ○ |

| Min. Splicing Nunbers for Long Distance Belt Splicing | ◎ | △ | ○ |

| Heat Resistance | ◎ | △ | ○ |

◎: Excellent, ○: Good, △: General

| Tensile Strength | Min. Tensile Stength (kg/cm) |

Elongation at 10% (Max.) |

Carcass Thickness (mm) |

Standard Thickness of Cover | Belt Thickness | Belt Weight (kg/M2) |

|

|---|---|---|---|---|---|---|---|

| Top Cover | Bottom Cover | ||||||

| KA 315 | 300 | 0.5 | 1.4 | 5 | 2 | 8.40 | 8.90 |

| KA 400 | 420 | 0.5 | 1.5 | 5 | 2 | 8.50 | 9.00 |

| KA 500 | 525 | 0.5 | 1.7 | 6 | 3 | 10.70 | 11.30 |

| KA 630 | 661 | 0.5 | 2.0 | 6 | 3 | 11.00 | 11.65 |

| KA 800 | 840 | 0.5 | 2.0 | 6 | 3 | 11.00 | 11.80 |

| KA 1000 | 1050 | 0.5 | 2.6 | 6 | 3 | 11.60 | 12.00 |

| KA 1250 | 1312 | 0.5 | 2.8 | 8 | 4 | 14.80 | 15.70 |

| KA 1400 | 1470 | 0.5 | 3.3 | 8 | 4 | 15.30 | 16.40 |

| KA 1600 | 1680 | 0.5 | 3.3 | 8 | 4 | 15.30 | 16.60 |

| KA 1800 | 1890 | 0.5 | 3.4 | 8 | 4 | 15.40 | 16.90 |

| KA 2000 | 2100 | 0.5 | 3.5 | 8 | 4 | 18.50 | 19.80 |

本網站會在您的電腦中放置我們的Cookie,幫助我們優化網站介面與使用者體驗。您進入此網站及表示同意Cookies的使用。